Thanks for the informative replies gents, much appreciated.

I will stick with a Dart block, although it may be overkill, I like the advancements in tech and reassurance of a newly manufactured part.

The 4.125 bore did tickle my fancy for a while, as 427 is easily achievable. However I'm going to get the 4.030 bore, buying me more rebuilds in the future.

Reference the cylinder heads, please bare with me as I ask a few why questions.

Below is a brief summary of some heads at 0.600 lift, purely for comparison.

Assuming 408W has 708 cfm theoretical max VE.

Edelbrock E-CNC - 584 cfm (total) = 82% VE

AFR 195 - 616 cfm (total) = 87% VE

AFR 205 - 630 cfm (total) = 88% VE

Based on the AFR 205 heads recommendation, is the 'tipping point' for heads in the high 80's percentage volumetric efficiency wise?

If I were to use AFR 205 heads, but 'restrict' them with an Edelbrock Air Gap dual plane (for drivability), I could always easily swap in a Victor/Victor Jnr. later over a weekend, and compare drivability/bottom end. This was an interesting read: https://www.streetmusclemag.com/tech-stories/stroked-and-choked-inches-and-intakes/

I realise engine building is not all math, and experience coupled with trial/error are also large factors, but given I'm in no rush to build, I would like to explore the reasoning behind component choices.

Thanks again,

Steve

Your approach is very logical and well thought out, but unfortunately some of it is a little hampered by the available info etc.

FLOW NUMBERS

Flow numbers are most useful when comparing numbers between the same mfg and/or where the numbers come from the same source. You can have a head flowed by 3 different shops and come up with 3 different numbers. Same thing with dyno testing an engine.

In addition to actual flow, the air speed is very important, an engine with high flow but low air speed will run like crap in the low and mid range compared to an engine with less flow and higher air speed. The 69 vs the 70 boss 302 engines are one mild example of this.

Also, it's important to compare flow numbers at .200 lift as well, and not just the "alleged" max flow numbers.

VOLUMETRIC EFFICIENCY.

Increasing compression increases volumetric efficiency but it may not tell you this in your book.

CYLINDER BORE SIZE

You will likely never have to rebuild this engine because it should easily go a minimum of 50,000 miles with your type of use, and the 4.125 block can be bored to 4.165, and the bore can be increased in size by as little as .005" each time you bore it if you use custom pistons, so you could theoretically bore a 4.125 block EIGHT MORE TIMES,

therefore, in this case you are really worrying about a problem that doesn't exist....unless you live to be around 874 years old.

VALVE SHROUDING

The bigger the bore, the farther away the edges of the valves will be from the cylinder walls. This increased distance will increase flow some because it won't be as obstructed by the cylinder wall.

AIR GAP VS VICTOR INTAKE & INTAKE PORTING

The air gap intake is arguably the best intake ever made for the majority of street builds, but it is not ideal for big displacement engines that are making even moderate power if they rev very far, so unfortunately one size does not fit all. This is not to say that the air gap is a horrible choice for your build, and it will work great...up to a point.

You can put an open plenum intake on a nearly box stock 302 engine and it will drive perfectly if it does not have a huge cam. I know this because I have had several. This is not ideal either but the point is that it won't run like crap at low rpm just because it is an open plenum.

If you build a 427 and use the moderate cam I posted and a victor open plenum intake, it will pull like a freight train right off idle with no low end "drivability" issues whatsoever, and it will rev to at least 6000 rpm, at which point most average (non racer) people would be very afraid.

All this being said, it is obviously not a huge cost or huge amount of labor to buy and change just the intake, so I would say that if you want to try an air gap to start with, because it definitely isn't a "mistake" per se, plus, if a victor intake would cause hood clearance issues, you could just get the air gap ported if you need clearance.

The 289/302 version of the air gap is different than the 351 version and the 351 version benefits more from proper porting than the 289/302 version does and a properly ported 351 version will flow just as much as a non ported victor senior. You can also think of a ported intake as cnc machined heads. They are not perfect s cast, and can benefit from cleaning up the flaws etc.

Chevy intake comparisons from Dr J.

RPM Air-Gap Victor Jr. Super Victor

Cast Ported Cast Ported Cast Ported

Runner

1 214 288 241 295 300 345

2 224 308 243 302 293 351

3 221 312 241 286 276 341

4 208 282 243 301 271 357

5 218 304 250 305 277 352

6 213 288 230 287 277 341

7 210 286 246 300 290 355

8 220 306 235 299 295 346

INTAKE SPACERS

As glenn mentioned, they can definitely increase power, and can do this on many intakes, but there are a few different designs to choose from.

MILLING THE CENTER DIVIDER IN AN INTAKE

Milling the center divider down around 20 mm or more in a dual plenum intake can sometimes improve overall performance, but this is another topic, and results can vary for each particular build, but this info may not be in your book either.

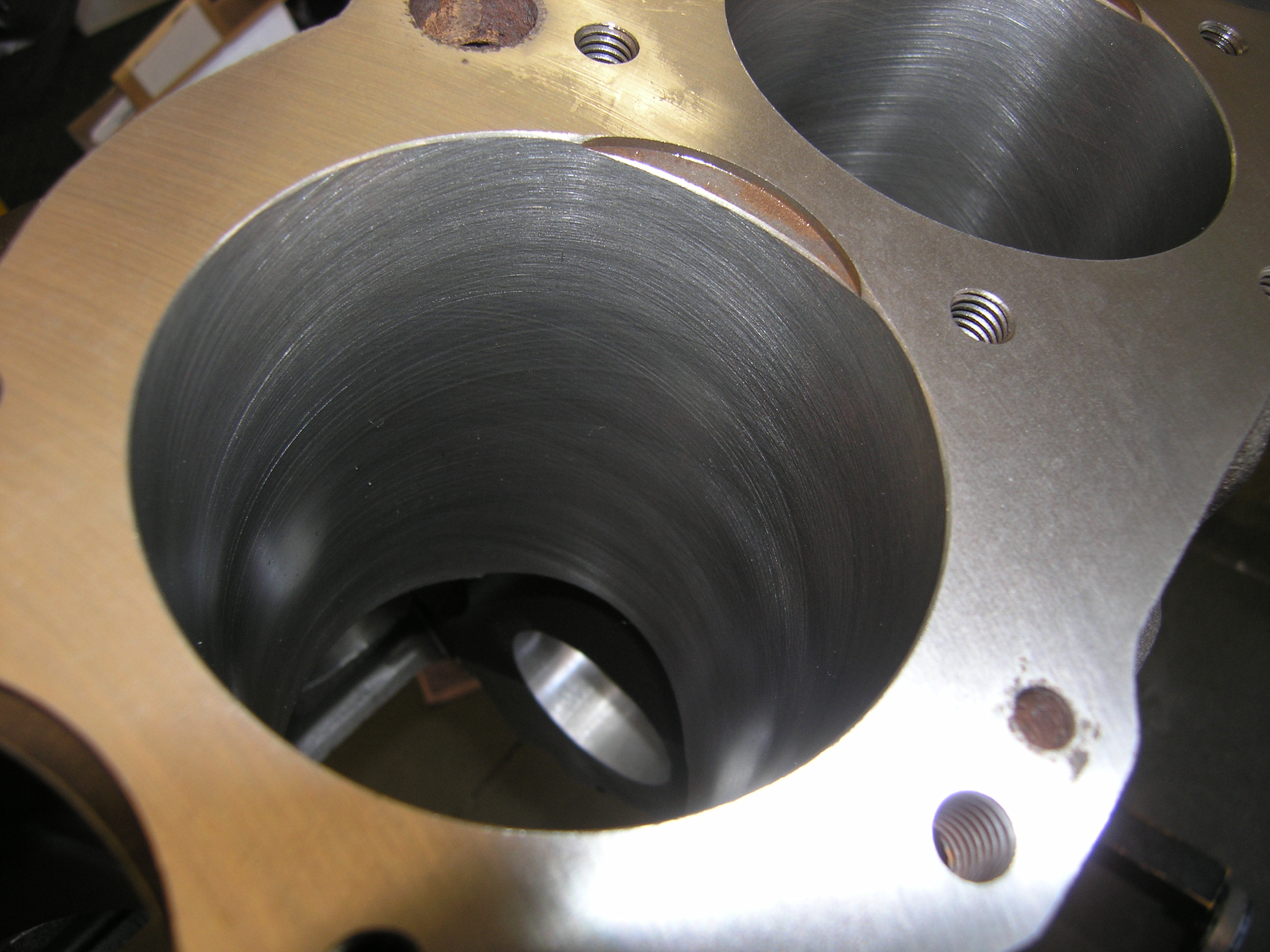

This is a stock 396 hp block. The valve relief is factory.

.